This is custom heading element

Originally developed by The British Institute Of Cleaning Science (BICSc) over 30 years ago was a universal colour code that would be recommended for use across the cleaning industry.

The principle behind colour coded cleaning is the process of designating colours to cleaning equipment in certain areas of a venue, reducing the spread of germs and increasing hygiene throughout an establishment.

Using a single mop to clean every floor in a restaurant, for example, can spread bacteria from the washrooms and toilets to kitchen and food preparation areas. This carries with it an inherent risk of cross contamination and consequently, illness. Applying a colour coded system to segregate sensitive areas from one-another is the most efficient and effective way of reducing the risk of cross contamination.

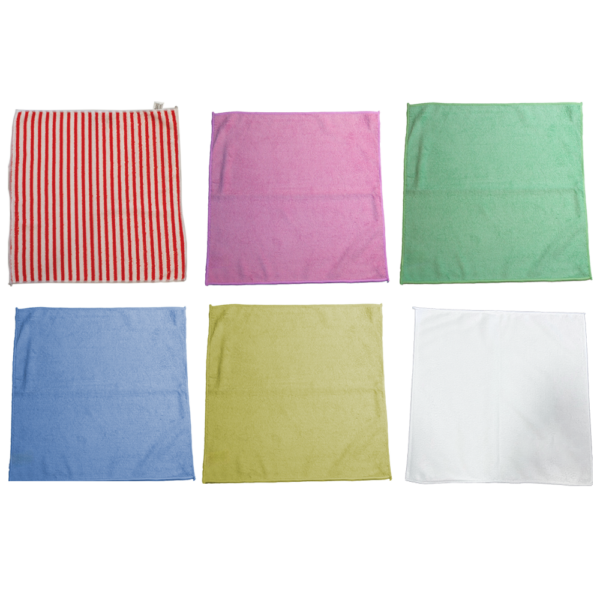

The original guidance consisted of four main colours; blue, green, red and yellow. These would be used to separate out specific areas such as bars, public areas, kitchens and washrooms.

Generally, these colours are sufficient to cover the most probable hazards, whilst creating an easily understood system. However the BICSc have recently updated their guidance to include an additional two colours of white and a striped cloth. This allows organisations to create bespoke, best practice cleaning protocols that may in some instances be more appropriate.

Inclusive Working & Best Practice

The inclusion of these additional colours into cleaning practices will also allow for a more inclusive working environment and caters for any potential user who may suffer from a colour vision deficiency commonly known as colour blindness.

Most people with colour vision deficiency have difficulty distinguishing between shades of red, yellow and green. This is known as “red-green” colour vision deficiency. It’s a common problem that affects around 1 in 12 men and 1 in 200 women.

Someone with this type of colour vision deficiency may find it hard to tell the difference between reds, oranges, yellows, browns and greens. This could cause issues for establishments who adopt colour coded cleaning procedures and poses a potential risk of cross contamination if the user has a colour vision deficiency.

Best practice for any cleaning company is to undergo a colour vision test for their staff in the form of the Ishihara test. This is where you’re asked to identify numbers contained within images made up of different coloured dots.

This will quickly establish whether colour coding procedures need to be modified for a particular individual to ensure the highest level of hygiene standards are maintained.

Try our colour blindness simulator below that demonstrates the potential difficulty people with a colour vision deficiency may face when implementing colour coded practices.

Colour Blindness Simulator

New & Improved

The different anomalous condition types are protanomaly, which is a reduced sensitivity to red light, deuteranomaly which is a reduced sensitivity to green light (the most common form of colour blindness) and tritanomaly which is a reduced sensitivity to blue light (extremely rare).

To facilitate such a situation we have now added two more colours to our trade favourite, Optima Proclean Shine microfibre cloths. Now available in the additional colours of white and a red and white striped option providing complete flexibility and a more inclusive environment for cleaning staff.

The Optima Proclean Shine Microfibre cloths really do live up to their name and will leave surfaces sparkling clean. These split weave cloths will remove up to 99.9% of bacteria with just water and are suitable for cleaning most surfaces. They can be extensively washed and can be considered one of the most effective and cost efficient cloths on the market.